Reverse Engineering: Shaping the Future with Innovative Solutions

Reverse Engineering: Shaping the Future with Innovative Solutions

In today's industrial world , product development, optimization of production processes and discovery of technological innovations are among the most important factors that increase competitiveness. Reverse engineering is the process of analyzing and redesigning and developing an existing product or system . This method has a wide range of applications in many areas, from industrial design to the defense industry, from the automotive industry to the medical sector .

As UMT Industrial, we offer innovative, cost-effective and sustainable solutions to our customers with reverse engineering solutions . We provide efficiency by using the latest technologies in the processes of digital modeling of existing parts, examination of their functions and production of improved versions .

What is Reverse Engineering?

Reverse engineering is an engineering discipline that aims to redesign and improve an existing product or system by examining its structure, components and operation .

In this process:

✔ Analysis of the product or component in a digital environment with 3D scanning and modeling

✔ Examination of its internal structure, material properties and production techniques

✔ Identification of the deficiencies of the original design and development

✔ Reproduction of the product or development of a superior version is provided.

In this way, components that have expired or for which spare parts are not available can be remanufactured, costs can be reduced and production processes can be optimized .

In Which Areas Is Reverse Engineering Used?

Reverse engineering is a method that has a wide range of uses in different industries :

1. Automotive and Aviation Industry

✔ Remanufacturing old or unavailable spare parts

✔ Analyzing and improving engine, chassis and other mechanical components

✔ Creating new designs using lightweight and durable materials

2. Defense and Space Technologies

✔ Redesign of end-of-life or discontinued systems

✔ Development of components for radar, weapon systems and unmanned aerial vehicles

✔ Modernization of high-security and durable equipment

3. Medical and Biomedical Technologies

✔ Production of personalized medical devices such as prostheses and implants

✔ Analysis of the components of medical devices and making them more efficient

✔ Development of patient-specific solutions using 3D printing technologies

4. Industrial Production and Machinery Industry

✔ Remanufacturing parts of outdated machines

✔ Designing lighter, more durable and energy efficient production components

✔ Upgrading parts to save costs in production processes

5. Electronics and Software Industry

✔ Analysis and development of circuit boards

✔ Making old systems compatible with new hardware

✔ Detection of security vulnerabilities and software updates

Reverse Engineering Process

The reverse engineering process generally consists of five basic steps :

1. Data Collection and 3D Scanning

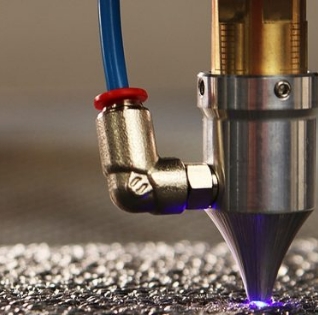

The product or component is digitally modeled using 3D laser scanners, optical scanners, or computed tomography (CT) devices .

2. Digital Modeling and CAD Design

Using the collected data, a 3D model is created with computer-aided design (CAD) software . Missing or worn parts are corrected and developed.

3. Material and Structural Analysis

The composition, strength and production method of the material are determined by mechanical and chemical analysis .

4. Planning the Production Process

The manufacturing techniques of the redesigned component are determined. Prototype production is carried out using methods such as 3D printing, CNC machining or casting.

5. Testing and Quality Control

The remanufactured component is subjected to performance tests compared with the original product and necessary improvements are made.

Reverse Engineering Solutions with UMT Industrial

As UMT Industrial, we offer high precision and innovative solutions for different areas of the industry with reverse engineering services .

✔ 3D Scanning and Modeling Services

✔ Material Analysis and Structural Reinforcement Solutions

✔ Spare Parts Production and Prototyping

✔ Production Optimization and Cost Reduction Strategies

✔ Special solutions for automotive, defense, medical and industrial sectors

Why UMT Industrial?

???? Cutting-edge Equipment: We use the latest technologies in 3D scanning, CAD modeling and prototyping processes.

???? Expert Engineer Staff: We successfully carry out the most complex projects with our experienced team in the field.

???? Cost and Efficiency-Focused Approach: We provide high efficiency at lower costs by improving your existing systems.

???? Special Solutions for Industrial Applications: We customize reverse engineering processes in accordance with sectoral needs.

Contact us to increase your competitiveness, optimize your production processes and develop high-tech solutions with reverse engineering!