Industrial Valves and Areas of Use

Control of fluids in industrial facilities is of great importance for the efficient and safe operation of systems. At this point, valves are the basic components used to direct, stop or control the pressure of liquids, gases, steam and chemicals.

As UMT Industrial, we offer high quality valve solutions suitable for energy, chemistry, water treatment, food, petrochemistry, pharmaceuticals and many other sectors. We support you to run your projects smoothly with reliable, durable and fully compatible valves with the system.

What is a Valve and What Does It Do?

A valve is a control element used to start, stop, direct, limit or regulate the flow in a fluid system . Valves can operate mechanically, pneumatically or automatically (electrically/actuated).

✔ Controls System Pressure

✔ Regulates Fluid Passage with On/Off Function

✔ Performs Routing and Zoning Function

✔ Increases Work Safety by Preventing Leaks

✔ Optimizes Energy and Water Consumption

Valve Solutions by UMT Industrial

With our wide range of products, we offer durable, long-lasting valve solutions that comply with international standards and are specific to your system needs .

1. Ball Valves

✔ It responds quickly in on/off operations.

✔ It works with low pressure loss.

✔ It is widely used in chemical, food, water and natural gas lines.

:small_blue_diamond: Advantages: Easy to use, compact structure, long life.

2. Butterfly Valves

✔ Ideal for large diameter pipelines.

✔ Compact design allows easy installation in narrow spaces.

✔ Suitable for water, air and light chemical fluids.

:small_blue_diamond: Advantages: Lightweight structure, fast control, low cost.

3. Gate Valves

✔ Used in fully open/fully closed systems.

✔ Low leakage risk and resistant to high temperature/pressure conditions.

✔ Used in systems carrying water, steam and liquids.

:small_blue_diamond: Advantages: Low maintenance, high flow capacity.

4. Globe Valves

✔ Suitable for gradual control of flow.

✔ Preferred in systems with high pressure drop.

✔ Used in steam, oil and pressurized water lines.

:small_blue_diamond: Advantages: Precise flow control, safe use.

5. Check Valves

✔ Ensures that the flow only moves in one direction.

✔ Increases system safety by preventing backflow.

✔ Plays an important role in protecting pumps.

:small_blue_diamond: Advantages: Automatic operation saves energy.

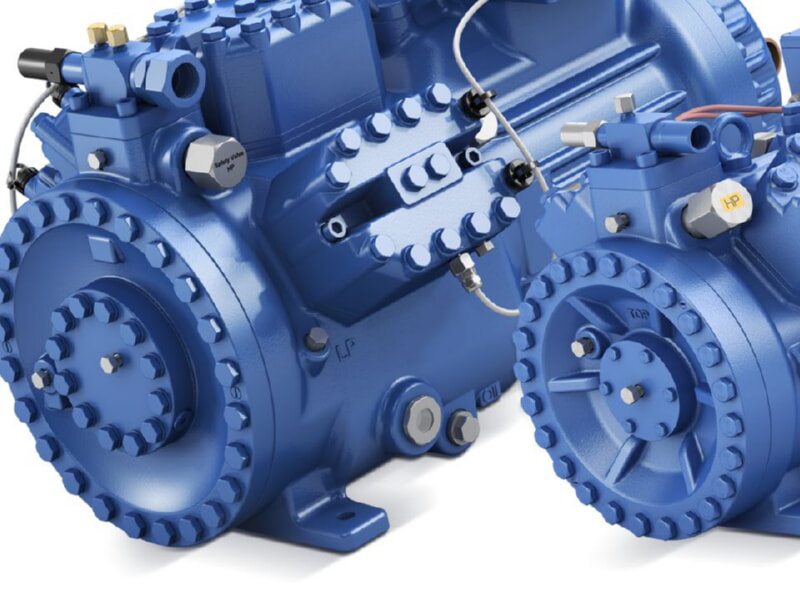

6. Pressure Reducing and Safety Valves

✔ Keeps the system pressure constant and protects the system in case of sudden pressure increases.

✔ Especially used in boilers, compressors and LPG systems.

:small_blue_diamond: Advantages: Security, extended system life, automatic balancing.

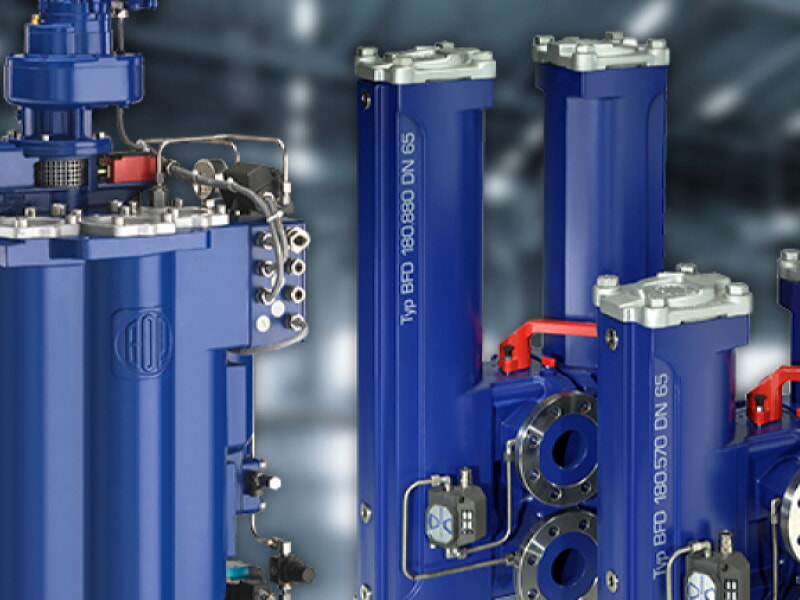

7. Actuator Valves (Electrical/Pneumatic Controlled)

✔ Can be integrated into automation systems.

✔ Can be controlled by remote control.

✔ Suitable for process automation and SCADA systems.

:small_blue_diamond: Advantages: Operational efficiency, remote control, process safety.

Areas of Use of Valves

✔ Water and Wastewater Management – In clean water, irrigation and sewerage lines.

✔ Petrochemical and Chemical Industry – In acid, base, solvent and gas lines.

✔ Energy Production – In steam boilers, thermal and hydroelectric power plants.

✔ Food and Beverage Industry – In liquid transportation systems with hygienic valve solutions.

✔ HVAC Systems – In heating, cooling and ventilation lines.

✔ Pharmaceutical and Medical Industry – In clean water and sterile environment applications.

✔ Automation and Process Facilities – In industrial control systems.