Quality Control, 3D Scanning and 3D Printer Technologies | UMT Industrial

In today's production technologies , high precision, efficiency and quality standards are of great importance. While quality control processes ensure accuracy at every stage of production, 3D scanning and 3D printer technologies offer revolutionary innovations in design and production processes.

As UMT Industrial, we respond to the evolving needs of the industry by offering Quality Control, 3D Scanning and 3D Printer solutions suitable for modern production processes. We help businesses optimize their production processes by using the latest technologies in precision measurement, rapid prototyping and production processes.

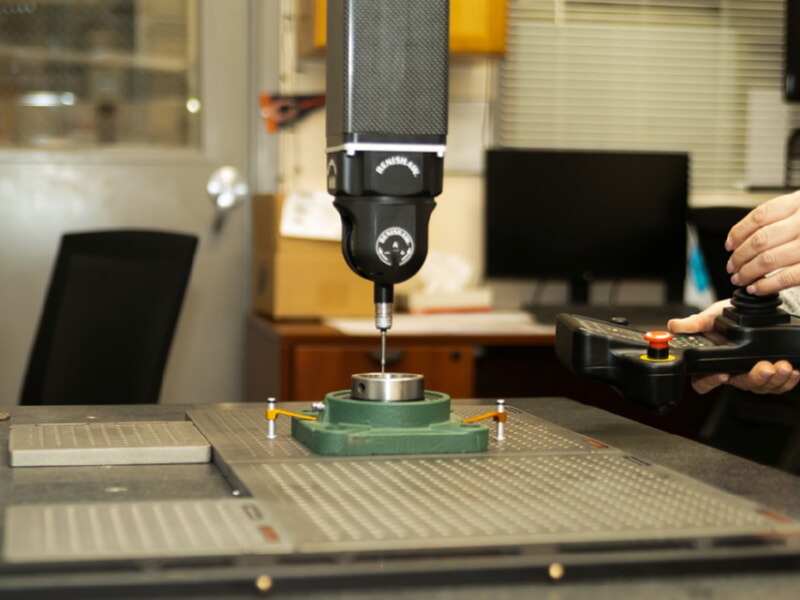

1. Quality Control and Measurement Technologies

Quality control is the testing and analysis processes implemented to minimize error rates in production, ensure compliance with standards and ensure that products are long-lasting and reliable .

✔ Measurement and Verification: High-precision measuring devices are used to determine whether products comply with tolerances.

✔ Visual Inspection and Reporting: Detailed analysis is performed to determine whether there are any defects or deformations on the product surface.

✔ Material Tests: Strength, hardness, temperature and chemical resistance of products are tested.

✔ Geometric Precision Control: It is examined whether the parts match the CAD models one-to-one.

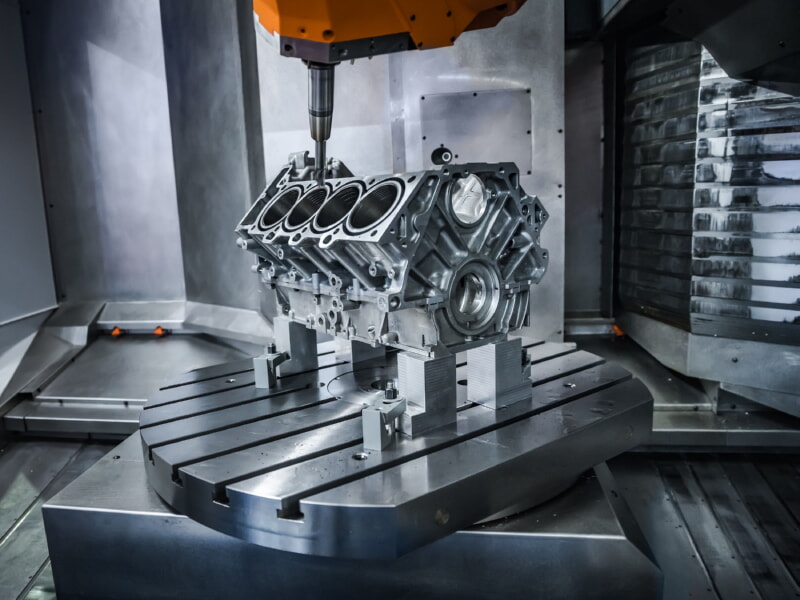

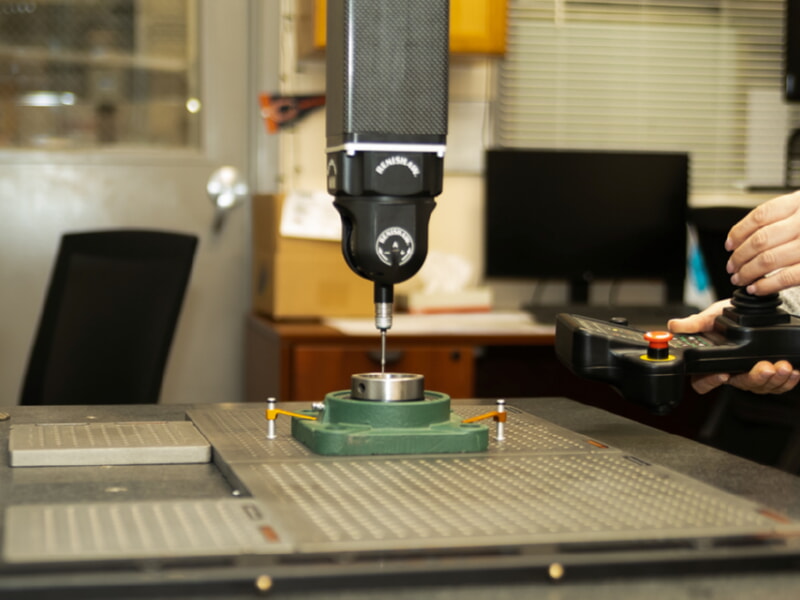

Equipment Used in Quality Control Processes

✔ Coordinate Measuring Machines (CMM) – Checks the accuracy of parts by performing high-precision 3D measurements.

✔ Optical and Laser Measurement Systems – Provides high accuracy in surface and dimensional analysis.

✔ X-ray and Ultrasonic Testing Devices – Detects whether there is deterioration or cracks in the internal structure.

✔ Visual Inspection Systems (AI Supported) – Provides instant quality control in production with artificial intelligence-supported systems.

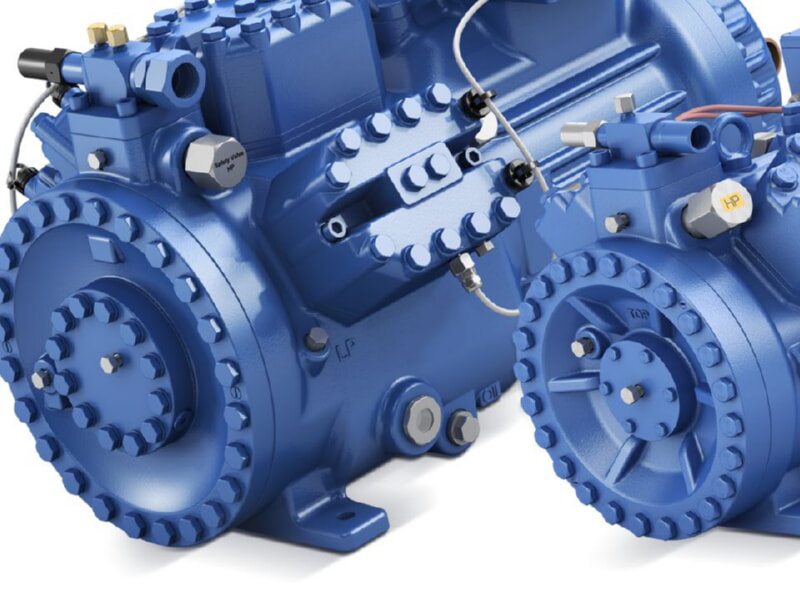

Areas of Use: Automotive, aviation, defense industry, medical devices, industrial production lines.

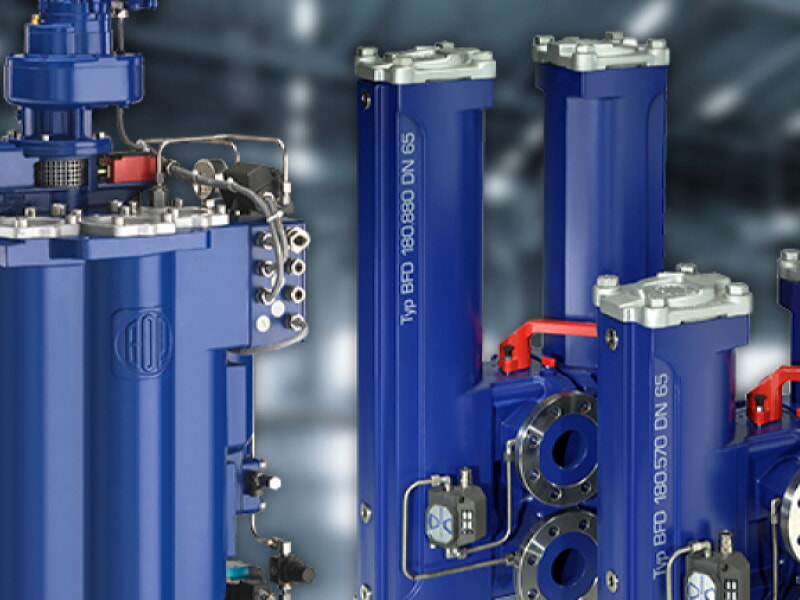

2. 3D Scanning Technology and Areas of Use

3D Scanning technology is one of the most innovative systems used to transfer physical objects to digital media. This technology allows precise measurements of parts to be taken and used in digital modeling, quality control and reverse engineering processes.

Advantages of 3D Scanning

✔ Fast and Precise Measurement: You can easily take detailed measurements of complex parts.

✔ Reverse Engineering: Provides digital modeling for the reproduction of old or broken parts.

✔ Improving Manufacturing Processes: It is possible to compare existing parts with CAD models and use them in quality control processes.

✔ Error Detection and Correction: Analyzes deformations or tolerance deviations that occur during production.

Our 3D Scanning Devices and Solutions

✔ Laser 3D Scanners: Provides micron-level precision with high-resolution scanning.

✔ Optical 3D Scanners: Can scan complex surfaces with light-based scanning technology.

✔ Handheld 3D Scanners: Provides easy scanning of moving parts.

✔ CT Scan (Computed Tomography Scanners): Performs detailed analysis of internal structures.

Areas of Use: Aviation, automotive, health technologies, industrial production, design and R&D studies.

3. 3D Printer Technologies and Rapid Prototyping

3D Printers offer revolutionary innovations in many areas from design to production, accelerating production processes and reducing costs.

✔ Rapid Prototyping: In product development processes, you can easily test design changes by accelerating prototype production.

✔ Customized Production: Provides cost advantage for one-time or small-scale production.

✔ Material Diversity: Provides the opportunity to produce with plastic, metal, ceramic and composite materials.

✔ Less Waste, More Sustainable Production: It wastes less material compared to traditional production methods.

3D Printer Types and Areas of Use

✔ FDM (Fused Deposition Modeling) Printers: Ideal for plastic-based production.

✔ SLA (Stereolithography) Printers: Use liquid resin technology for high-resolution precision production.

✔ SLS (Selective Laser Sintering) Printers: Enable the production of complex geometries with powder-based materials.

✔ DMLS (Direct Metal Laser Sintering) Printers: Enable layered production of metal parts.

✔ PolyJet Printers: Suitable for multi-color and multi-material production.

Areas of Use: Aerospace and defense industry, medical implant production, automotive, engineering and design applications, architectural modeling.

Technological Production Solutions with UMT Industrial

As UMT Industrial, we offer quality control systems, 3D scanning technologies and 3D printer solutions suitable for modern production processes. We add value to your businesses by using the latest technologies to make your production processes more efficient, precise and cost-effective.

Why UMT Industrial?

Wide Range of Products: We offer quality control equipment, 3D scanning devices and 3D printer solutions.

High Precision and Quality: We provide industrial solutions with the latest technology equipment.

Technical Support and Consultancy: We help you determine the best technologies for your production processes.

Fast and Reliable Supply: We ensure the uninterrupted progress of your projects with fast delivery from stock.

Competitive Prices: We offer high-tech solutions with the best price guarantee.