Sealing Elements and Industrial Usage Areas

In many sectors such as industrial machinery, hydraulic and pneumatic systems, power plants and automotive , sealing elements play a critical role in ensuring the safe transportation of fluids. O-rings, gaskets, control valve parts and felts prevent leakage of oil, water, gas and chemicals in systems, providing a safe and efficient working environment.

As UMT Industrial, we offer high-performance sealing solutions suitable for the needs of different sectors. We ensure the safe operation of your machines and systems with durable, long-lasting sealing elements that comply with industrial standards.

Importance and Advantages of Sealing Elements

✔ Ensures System Safety – Reduces equipment damage and occupational safety risks by preventing leaks.

✔ Prevents Energy and Fluid Loss – Reduces costs by preventing oil, air, water and chemical substances from leaking.

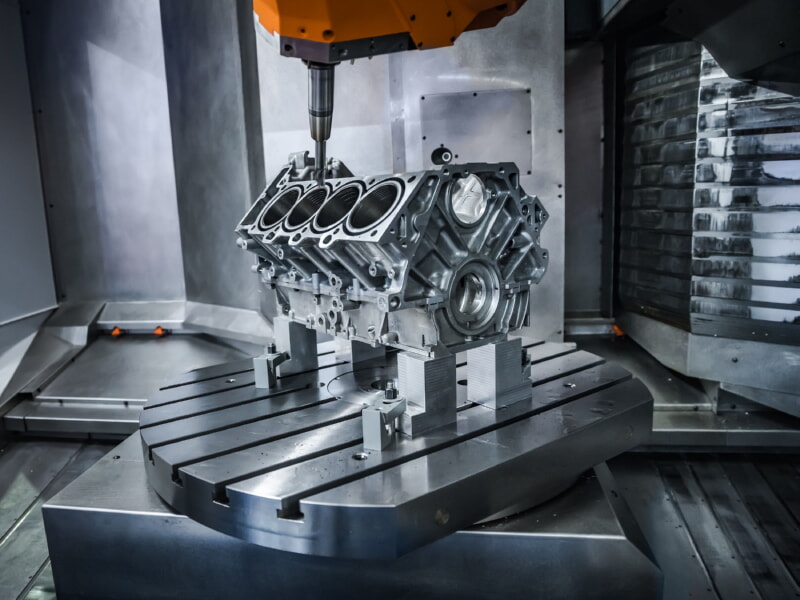

✔ Extends Machine and Equipment Life – Provides long-term use by resisting friction and wear.

✔ Resistant to High Pressure and Temperature – Resists intense pressure and temperature changes in industrial environments.

✔ Environmentally Friendly – Minimizes environmental damage by preventing chemical and fluid leaks.

UMT Industrial's Sealing Solutions

As UMT Industrial, we supply the most suitable sealing elements for industrial facilities and production lines. Our sealing products, produced with high quality materials, provide maximum durability against the most difficult conditions.

1. O-Ringler

✔ Produced with different diameter and material options.

✔ Provides excellent performance in systems requiring chemical resistance.

✔ Suitable for static and dynamic sealing applications.

Areas of Use: Hydraulic and pneumatic systems, oil and gas industry, food and pharmaceutical industry.

2. Gaskets (Flat Gasket, Spiral Wound Gasket, PTFE Gaskets)

✔ High temperature and pressure resistant gaskets are available.

✔ Offers different material options such as metallic, rubber and PTFE.

✔ Provides perfect sealing in flange connections.

Areas of Use: Steam systems, pipelines, chemical plants, water treatment systems.

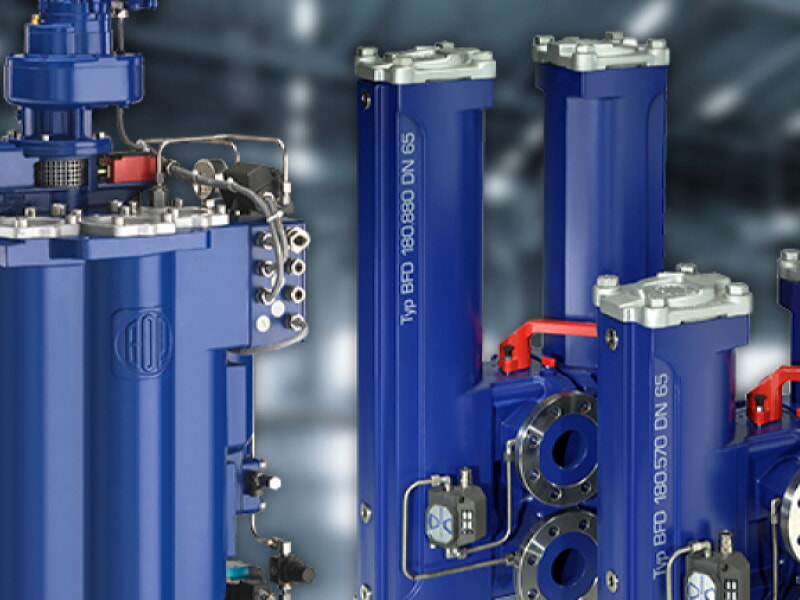

3. Control Valve Parts (Diaphragms, Valve Seals, Sealing Rings)

✔ They are durable sealing elements specially produced for industrial valves.

✔ They are resistant to abrasion and chemicals.

✔ They are long-lasting in high-pressure systems.

Areas of Use: Power plants, refineries, petrochemical plants, water treatment systems.

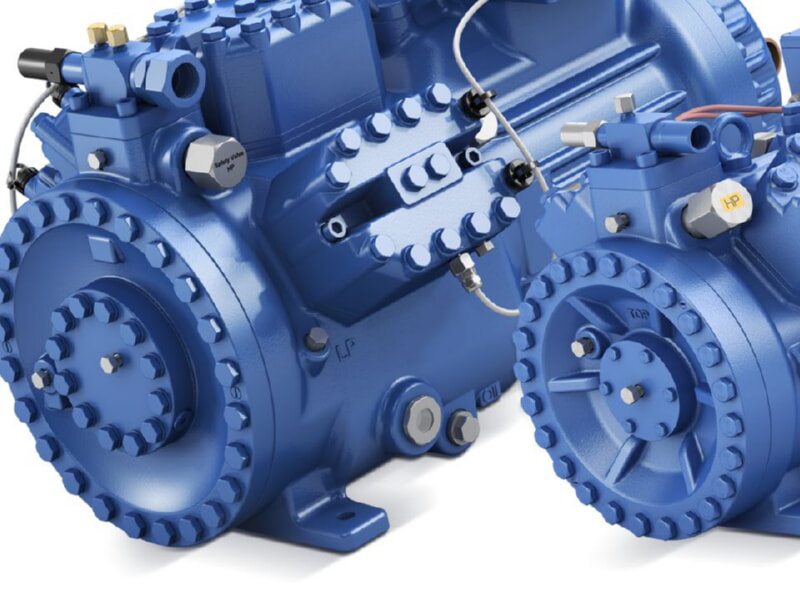

4. Seals (Oil Seals, Hydraulic Seals, Pneumatic Seals)

✔ Provides perfect sealing in rotary and linear motion systems.

✔ Manufactured with materials resistant to abrasion, chemicals and temperature.

✔ Special designs are available for hydraulic and pneumatic applications.

Areas of Use: Automotive industry, machinery manufacturing, mining, construction machinery.

Areas of Use of Sealing Elements

✔ Hydraulic and Pneumatic Systems: O-Rings, seals and gaskets are used in hydraulic cylinders and pneumatic systems.

✔ Automotive Industry: Provides sealing in engine, transmission and brake systems.

✔ Chemical and Petrochemical Plants: Provides safe transportation of chemical substances.

✔ Food and Pharmaceutical Industry: Hygienic seals and O-Rings are used in food and pharmaceutical production lines.

✔ Water and Wastewater Treatment Systems: Provides water tightness in valves, pumps and pipe systems.

✔ Energy Production and Refineries: High temperature and pressure resistant gaskets and gaskets are used.

Safe and Efficient Sealing Solutions with UMT Industrial

As UMT Industrial, we offer high-performance sealing elements for all areas of industry. We provide the highest quality products to ensure the smooth operation of your machines, piping systems and production lines.